SWA39 CT

Modular fixating system for computed tomography and the CT-Multi-Tower

The standard program SWA39 with more than 200 products is the basis for the CT fixating system from dk. In industrial computed tomography, these modules also form the most advanced modular system for clamping devices for the secure holding of all types of parts.

If you want to scan as many test parts as possible in just one inspection programme, the CT-Multi-Tower is ideally.

SWA39 CT – Modular fixating system

Advantages of the dk system

» CT suitable workpiece holder

Modules developed especially, in terms of geometry and materials for industrial computed tomography: Completely or, especially in the transition from workpiece to holder, the fixation elements have a significantly lower degradation coefficient than the test specimen. The part to be examined is thus clearly distinguishable in the scan. In addition, the geometrically precisely defined clamping elements form the basis for their later exclusion from the overall result if this should become necessary for special parts and processes.

» Professional module system

Modules which are precisely matched to each other are connected over standard interfaces. Instead of an unstable, short-life and non-adjustable combination of force and form clamping knocked together from soft foams, the dk system enables the professional construction of precise, safe and reusable fixtures.

» Rapid, simple and secure structures

The logical separation into adjustment elements, clamping function units and workpiece holders make the system easy to understand and practical for everyone. Each employee can effortlessly assemble a stable clamping fixture in a short time, securely clamp the test piece, align it into position and inclination and readjust it if necessary.

» Repeat accuracy

When several workpieces are to be scanned in series, the clamping position remains identical. This can only ease the testing task.

» Reproducible construction

Fixtures can be completely dismantled and the elements used for other devices. Once constructed, a clamping configuration can be reproduced at any time. Many adjustable elements have scales to aid this.

» High service life

The basic, clamping and holding elements are wear-resistant. They can therefore be repeatedly used over many years and so, save costs and resources.

Application examples

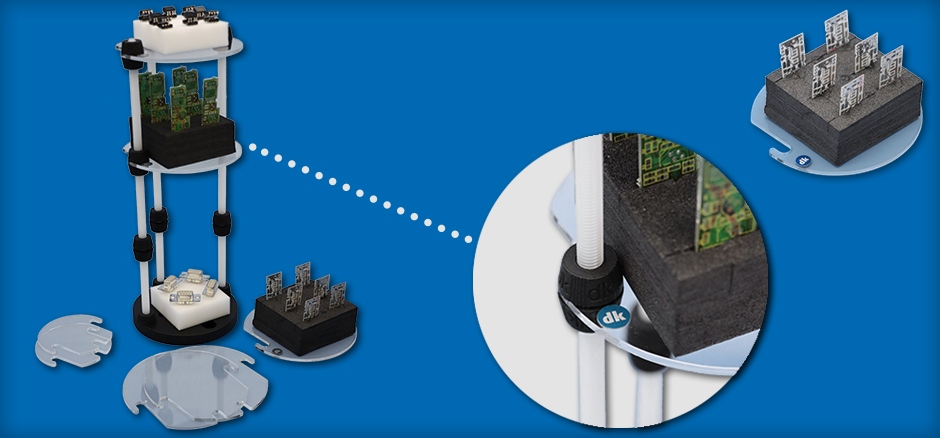

SWA39 CT – Multi-Tower

In line with the rapid development of industrial computer tomography, after successfully positioning the SWA 39 CT module system for the quick and easy fixation of test specimens using X-ray transparent modules, the challenge now is to scan as many test specimens as possible in one go. Ideally, using the Z-axis potential, several batches of test specimens would be positioned over each other in order to scan them – e.g. overnight – using an inspection programme.

The second objective is to increase productive machine time by setting up outside the machine. There are then three possibilities for exchanging the fully equipped tower in the CT in a matter of seconds:

- Without interface, thanks to the solid base plate, the CT-Tower stands quickly and securely on the turntable.

- With an SWA39 interface, the CT-Tower can be changed quickly and fixated securely and precisely centred.

- With the self-centring taper attachment, the change is not only rapid, secure and centred, but can also be carried out automatically by a robot.

A fourth variant for the quick change of test part carriers is the exchange of individually equipped levels of the CT-Multi-Tower, which can be secured and released again very easily.

Perfect infinitely variable height adjustment with simultaneous maximum stability of the overall construction

- » Instead of 1 level, several levels stacked over each other (= tower), which are scanned one after the other according to the programme sequence

- » Instead of several levels placed at a fixed distance, levels that are infinitely variable in height

- » Easy tool-free exchange of these individual carrier levels within seconds using simple clamp connections

- » Easy tool-free exchange of the entire tower within seconds by means of SWA39 quick-change interfaces or self-centring taper mounts, which are also suitable for automation using robotics

Advantages of the CT-Multi-Tower

- » Minimisation of the process time for the CT scan, because multiple parts can be tested without set-up expenditure compared to using only one level

- » Maximum fill capacity, because each level only has the exact height required for the dimensions of the parts on this level

- » Maximising productive machine time for faster processes at lower costs

dk offers even more measuring technology solutions!

You can find all our other products as well as product information in our catalogue.