Four-jaw chuck for optical metrology

Manual chucks come under the standards for optical and tactile metrology, therefore the modular system of the dk fixing range does so as well. Now we extended product range for optical metrology with the precision four-jaw chucks.

What are the requirements for four-jaw chucks?

In general machine construction, the concentric four-jaw chuck is given the following two main tasks:

>> Clamping square materials

>> Clamping workpieces which are sensitive to deformation

In optical metrology, one factor is essential:

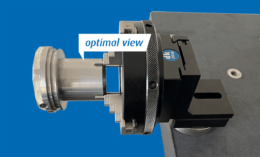

>> The view through the centre of the chuck

Why is the view at the centre important?

Optical measurement is an easy task if the workpiece is being checked in transmitted light or, generally speaking, if there is a clear contrast with the environment. With an ordinary three-jaw chuck, however, there is always one jaw behind the end of the workpiece – this is not an optimal scenario.

The perfect scenario would be where the space behind the end of the centre axis of the workpiece is kept as clear as possible – and this is what we have with the four-jaw chuck.

What other advantages do the manual four-jaw chucks from dk have?

>> The optional standard SWA39 interface, which means the chuck can be adapted to all the quick clamping fixtures and setup

and adjusting elements in the dk modular system

>> An integrated pin hole with three sets of pins of varying length, which make it possible to hold the workpiece above the

jaws as well

>> Jaws can be reversed without tools

>> Suitable blanks are supplied for machining by the customer for special workpieces and processes