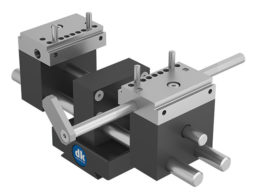

The precision centric vice

The precision centric vice holds any workpiece so that it is accessible from all sides. For optimum measuring from all sides without having to reposition the part.

The centric vice was developed to ensure that the workpiece fixation is optimised to better facilitate the overall process:

In contrast to standard vices, the centric vice always positions parts of different sizes in the symmetrical centre of the vice.This means that the centre line of any workpiece is always in the same position within this self-centring clamping element.Repositioning when changing from small to large parts is no longer necessary.

The SWA39 quick change interface makes the vice fully compatible with the entire dk module system and, through these elements enables fully spatial positioning.

A large selection of jaw plate types enables positive clamping of workpieces and reduces the clamping force required for a secure hold.

The standard jaws have holes for pins to elevated parts so that they can be clearly seen and accessed tactilely from all sides.