News → Automated quick-change interface SWA40

For use with robots in the context of CMMs, optical measuring machines, computer tomographs, surface and contour measuring devices, and 3D scanning systems.

» Perfect integration of the measuring machine into the overall process

» Orderly provision of test specimens at the measuring machine

» Optimal movement into the measuring machine

» Repeatable positioning and fixing

» Controlled removal/deposition depending on the measurement result

» Easy integration thanks to universal quick-change interface

The universal interface between machine and workpiece thanks to numerous basic holders for all measuring technologies. Fully compatible with the dk modular systems, enabling countless fixing devices.

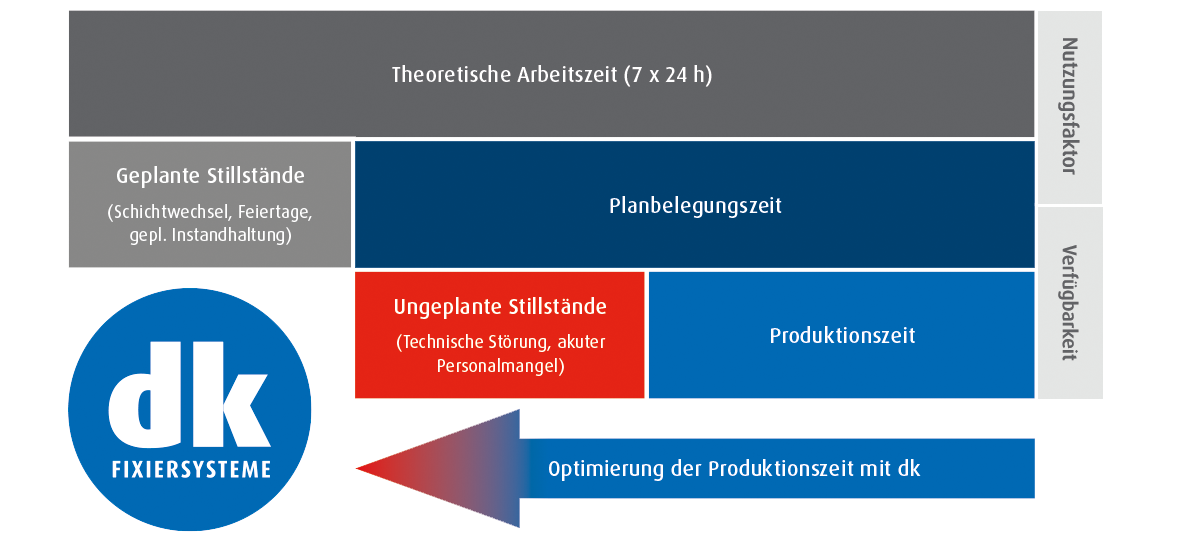

» Operation without measurement technology personnel for production-related measurement saves time.

» The operator sets up in the staging area when it fits into his or her workflow.

» Unmanned measurement processes without personnel costs.

» Unmanned processes in additional shifts or outside regular working hours.

» Consistent process quality because programmed processes always run exactly the same way.

» For all measurement technologies

» For all measuring machines, regardless of manufacturer

» For all industrial robots, regardless of manufacturer

» For all part carriers of the many dk modular systems and thus…

» For all types and geometries of test pieces

» For single and multiple clamping

» For simple programming, as grippers and robots are

oriented not to the test piece but to the interface

Login