News → Variable-fixed 3D camera mount

Embedded vision – smart image processing systems that are integrated directly into machines and systems teach devices to ‘see’! Optics, data links and software are at the heart of rapid developments at countless tech companies. But who takes care of the mechanical interface to the industrial device? Who brings the camera and machine together in such a way that all installation situations can be universally realised with just a few standard components?

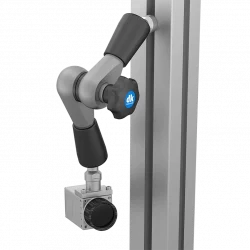

dk shows how, with just one fixing element, almost any camera position, no matter how complex, can be easily generated, simply adjusted and permanently fixed in place. And this is significantly cheaper than using rigid camera mounts that are designed specifically for particular systems and processes and are custom-made, meaning they cannot be readjusted!

» Technically simple and universal connection to machine and camera

» Positioning of the camera spatially independent of the machine frame

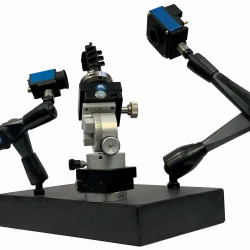

» Unlimited variable camera alignment in 3D space

» Selection of different action radii

» INOX versions available for clean zones and clean rooms

» Tool-free fixation of camera movement from easily adjustable to completely fixed

The level of ‘absolutely solid’ is in the range of welded parts

» Each fixing can be readjusted and dismantled without tools

The solution is a 3D camera mount with special technical features – in particular, the mechanical central tensioning of three joints designed for maximum force.

dk has developed programmes for these 3D joints with radii of action ranging from 100 to 600 mm in three material and two technical variants. The TurnStop technology in particular delivers maximum strength through the combination of form and force closure in the precision joints.

And the new INOX HygienicLine offers all the features required for clean rooms and clean environments.

» Standard holders for all areas of application instead of machine-specific special solutions

» Virtually unrestricted positioning of the camera in the engine room

» Bridging even larger and geometrically complex distances

» Perfectly infinitely adjustable alignment via three individual joints

» Simple operation

» Completely rigid and secure final state, yet still adjustable

» Completely rigid and secure final state

» Can still be used after modifications or dismantling

» INOX solutions for clean rooms and clean areas in high-tech and micro-industries

The advantages over cheap joints, standard angles and special solutions milled from solid blocks are more than obvious. The costs are offset by versatility, speed, long-term reliable function and repeated usability.

This is entirely in line with dk’s principle: ‘FAST REASSEMBLY LIFELONG’.

Login