SPEZIALFIX

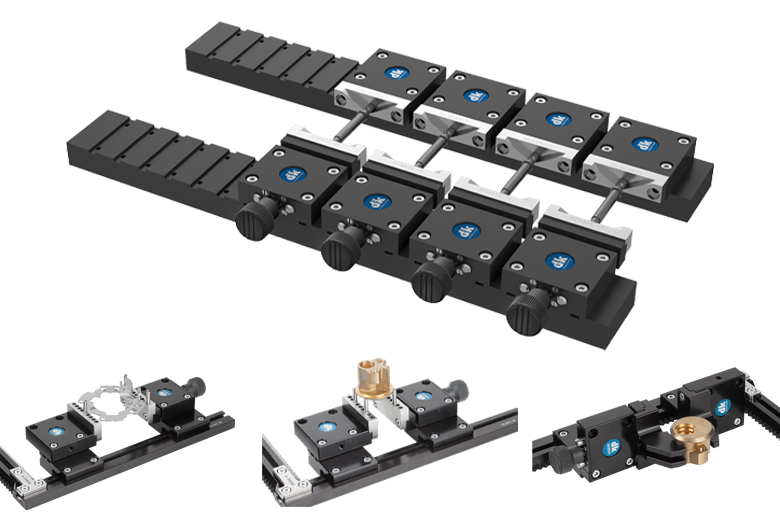

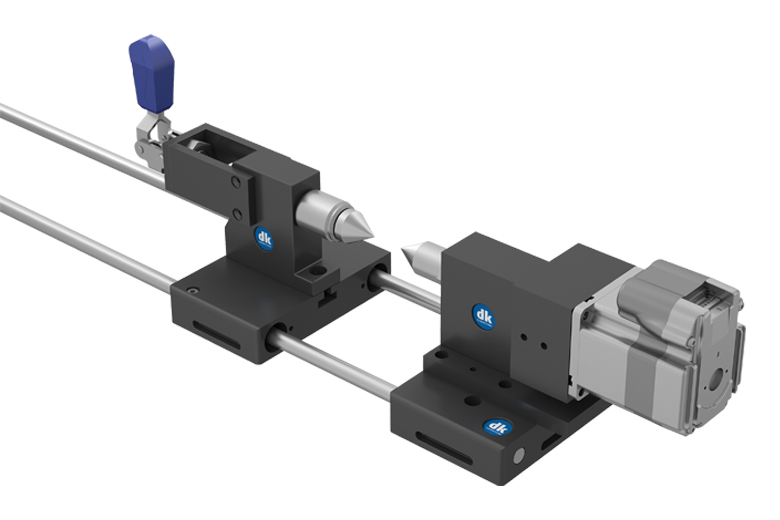

» Economical solutions using components from the dk standard ranges

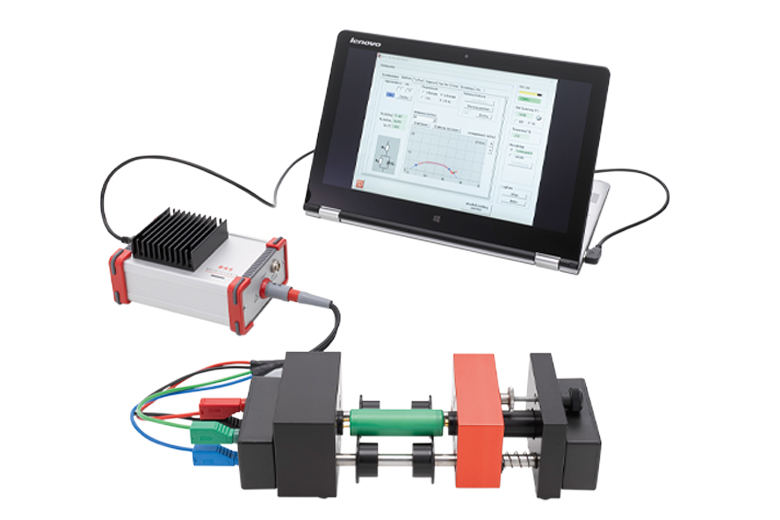

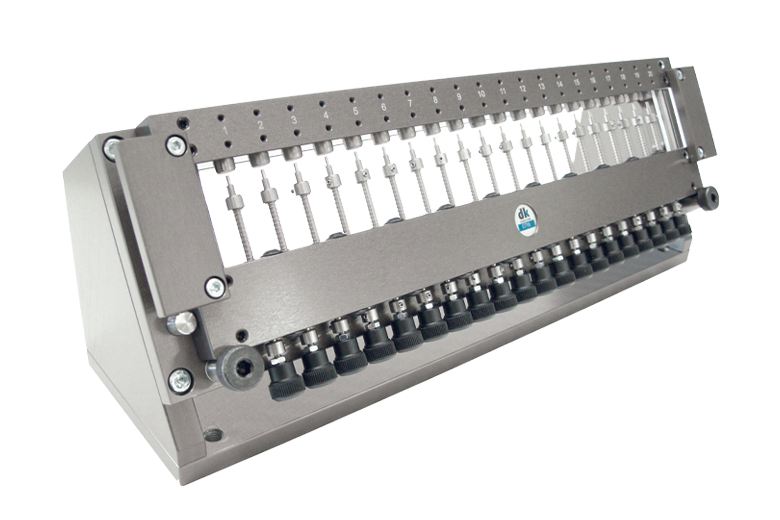

» Measuring tables for mobile measuring equipment for direct mounting of test parts using standard and special fixing elements

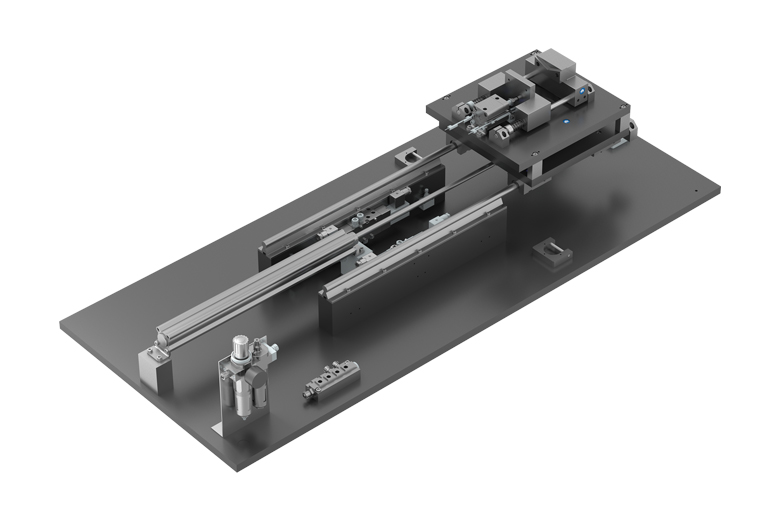

» Improved overall equipment effectiveness thanks to automation using linear and robotic technology

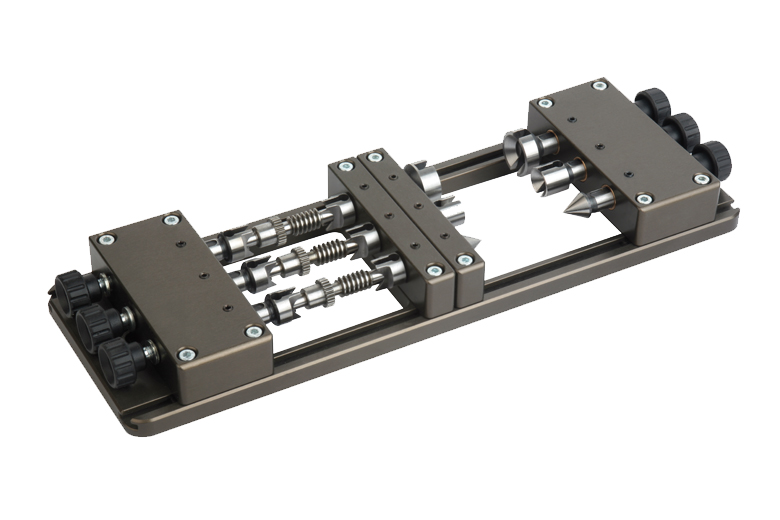

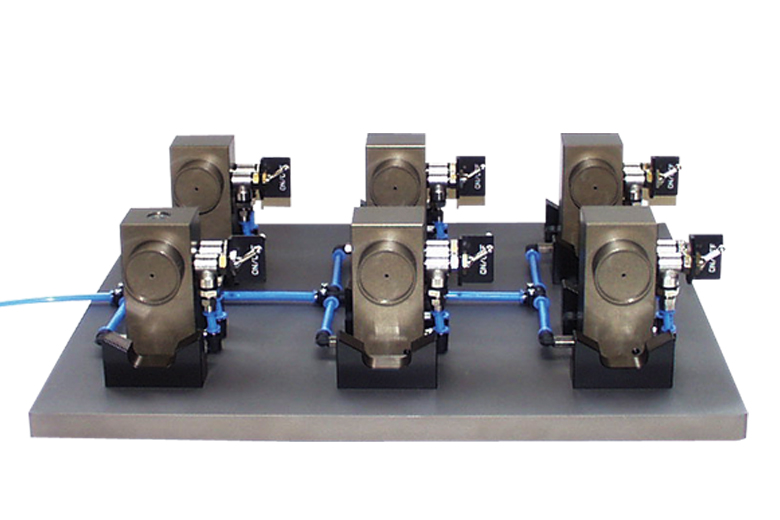

» We develop, design and manufacture special clamping devices according to your specifications

» Testing and measuring fixtures, analysis stations, inspection and test gauges

» Simple or complex multi-clamping systems with mechanical, pneumatic, electromechanical or combined fixturing, clamping and handling components

Realize your individual special fixture together with us!

Login