Modular clamping systems for measurement technology

Modular clamping systems for measurement technology

Modular clamping systems for measurement technology

On the market since 1972, the dk team has been involved in fixing technologies from an early stage

and has continued to develop this product range over time.

further developed. Today, the range comprises around 1,000 products,

which can be freely combined to form a modular system.

Users who work with dk technology regularly confirm this:

Flexible combination options for the modules and the durability of the

elements guarantee precise measurement results with a fast workflow.

fast.

reassembly.

lifelong.

The basic principle of all dk fixing systems.

Our devices have a modular design,

can be dismantled at any time and can be identically

reassembled identically.

The compatibility of the dk fixing systems

the utility value is perfect.

Our devices have a modular design,

can be dismantled at any time and can be identically

reassembled identically.

The compatibility of the dk fixing systems

the utility value is perfect.

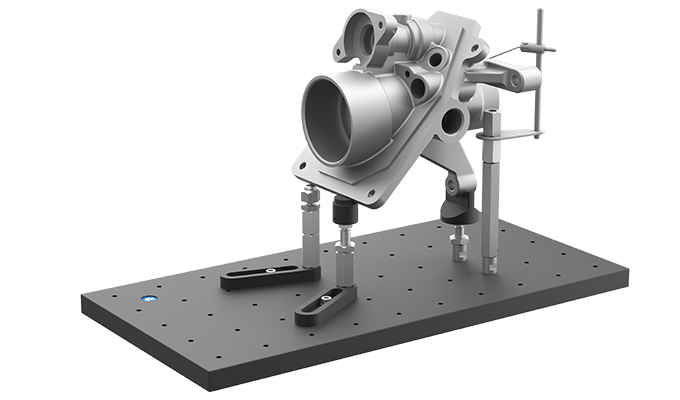

Primarily used on medium to large coordinate measuring machines (CMMs) for dimensional workpiece testing.

The fixture, which can be individually configured to meet specific requirements thanks to the wide range of components, holds the test piece securely and with repeatable accuracy. It is space-saving, allowing maximum accessibility to the test piece.

Modular system suitable for one-off measurements (e.g., prototypes, batch sizes of 1, and very small series) thanks to quick setup and dismantling.

Modular system suitable for series measurements (recurring larger production quantities) with repeatable positioning of the test pieces and a reproducible overall clamping device design.

Applicable to small to medium-sized tactile measuring machines and multi-sensor devices.

Thanks to the wide range of components, the fixture can be individually configured to meet specific requirements. It holds the test piece securely and with repeatable accuracy. It is space-saving, allowing maximum accessibility to the test piece.

Modular system suitable for one-off measurements (e.g., prototypes, batch sizes of 1, and very small series) thanks to quick setup and dismantling.

Modular system suitable for series measurements (recurring larger production quantities) thanks to repeatable positioning of the test pieces and a reproducible overall clamping device design.

<p>Applicable to optical coordinate measuring systems, multi-sensor measuring machines, digital measuring projectors, and digital microscopes.<br />The fixture, which can be individually configured to meet specific requirements thanks to the wide range of components, holds the test piece securely and with repeatable accuracy. It is space-saving, ensuring maximum accessibility.<br />Modular system suitable for one-off measurements (e.g., prototypes, batch sizes of 1, and very small series) thanks to quick setup and dismantling.<br />Modular system suitable for series measurements (recurring larger production quantities) thanks to repeatable positioning of the test pieces and the reproducible overall design of the clamping device.</p>

For use on tactile and optical contour/form and roughness measuring devices.

The fixture, which can be individually configured to meet specific requirements thanks to the wide range of components, holds the test piece securely and with repeatable accuracy. It is space-saving, ensuring maximum accessibility.

The modular system is suitable for one-off measurements (e.g., prototypes, batch sizes of one, and very small series) thanks to quick setup and dismantling.

The modular system is suitable for series measurements (recurring larger production quantities) thanks to the repeatable positioning of the test pieces and the reproducible overall design of the clamping device.

For use on tactile and optical contour/form and roughness measuring devices.

The fixture, which can be individually configured to meet specific requirements thanks to the wide range of components, holds the test piece securely and with repeatable accuracy. It is space-saving, ensuring maximum accessibility.

The modular system is suitable for one-off measurements (e.g., prototypes, batch sizes of one, and very small series) thanks to quick setup and dismantling.

The modular system is suitable for series measurements (recurring larger production quantities) thanks to the repeatable positioning of the test pieces and the reproducible overall design of the clamping device.

For use on tactile and optical contour/form and roughness measuring devices.

The fixture, which can be individually configured to meet specific requirements thanks to the wide range of components, holds the test piece securely and with repeatable accuracy. It is space-saving, ensuring maximum accessibility.

The modular system is suitable for one-off measurements (e.g., prototypes, batch sizes of one, and very small series) thanks to quick setup and dismantling.

The modular system is suitable for series measurements (recurring larger production quantities) thanks to the repeatable positioning of the test pieces and the reproducible overall design of the clamping device.

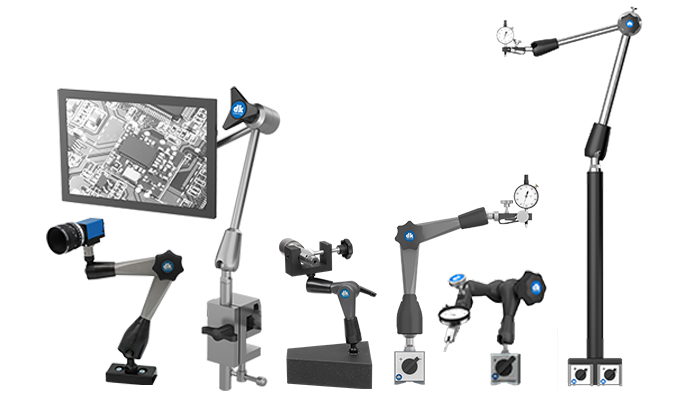

Applications in all areas of industrial image processing and non-contact measurement and testing technology, especially inline measurement technology.

For the assembly and positioning of cameras, sensors, lighting, end-of-arm robot tools, and much more.

The modular systems, which can be individually configured thanks to a wide selection of components, are suitable for both project planning (proof of concept) and, especially, for rigorous industrial use (field application).

For every application, there are programs tailored to the requirements of each application area, which can also be combined with one another.

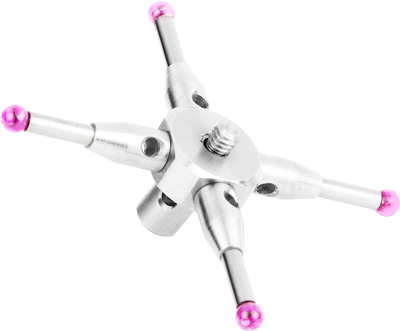

You are here: → For use with robots in the context of CMMs, optical measuring machines, computer tomographs, surface and contour measuring devices, and 3D scanning systems. Optimisation of the entire process chain » Perfect integration of the measuring machine

Login